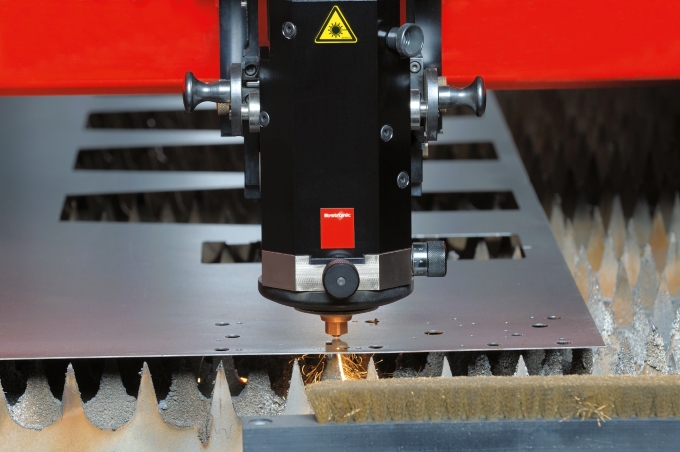

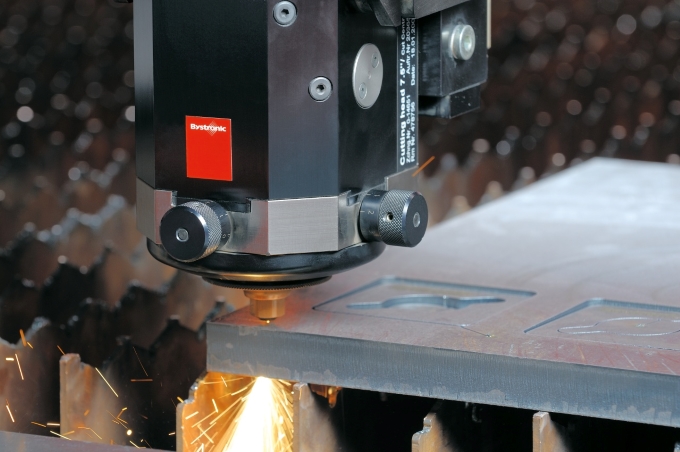

FLAT SHEET LASER CUTTING

Four machines with the ability to cut a huge range of materials

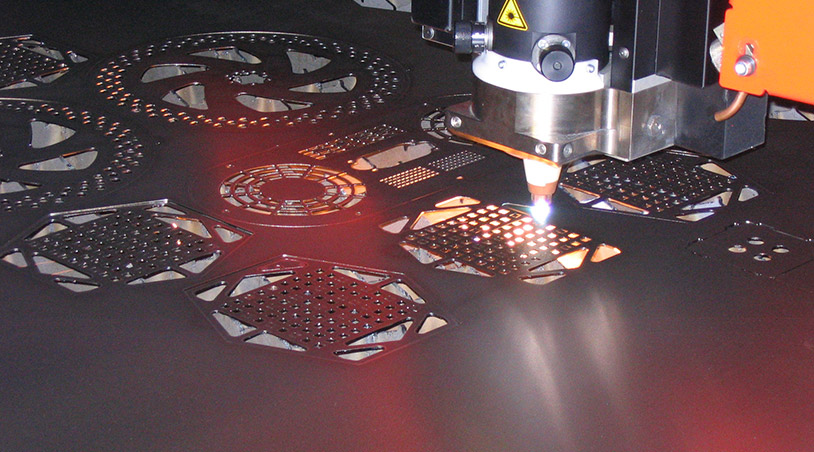

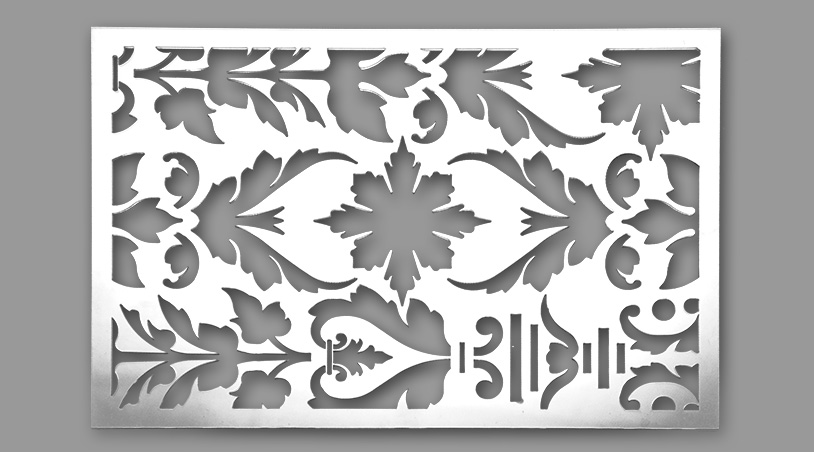

If you require clean precise shapes cut from flat sheet materials, laser cutting is the solution for you! Forget guillotines, grinders and hacksaws – laser cutting is the smart way to produce your flat sheet components. Using specialised programming software and high speed precision Swiss machinery, your parts will be ready on time, every time.

More information

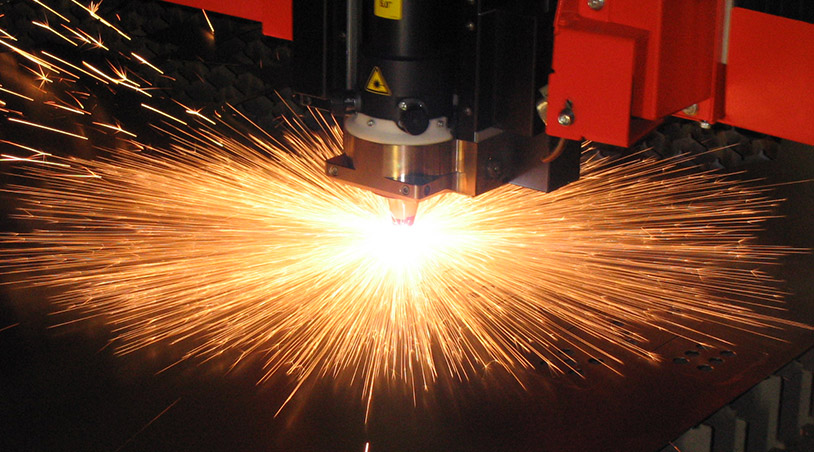

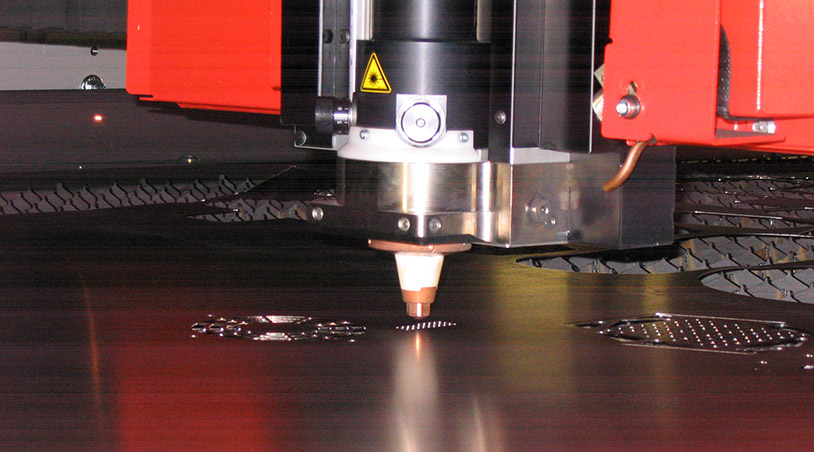

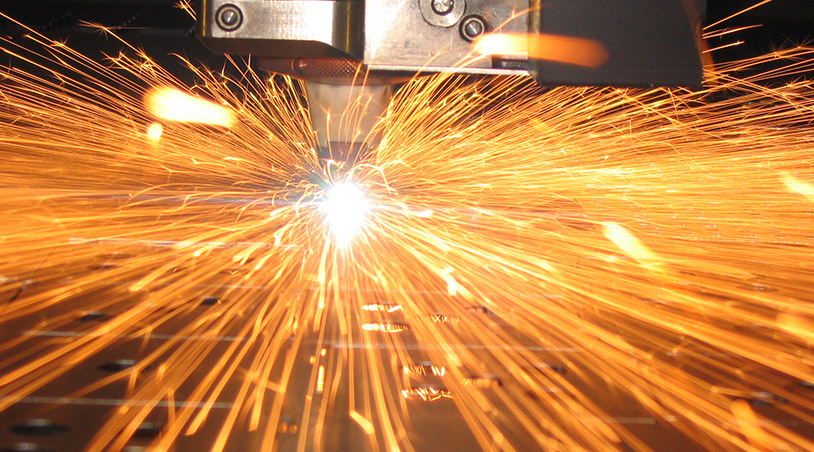

Laser cutting produces square, clean and burr free edges with minimal heat input to the surrounding material. It is fast, quiet and highly efficient. It suits a large variety of material types and creates very accurate results with minimal waste.

How It Works

A high power CO2 laser beam is directed via a series of fixed and moving mirrors to the cutting head. Our Fiber laser uses a solid state source and fiber optic to transmit the beam to the head. Here, the beam is focused to a pinpoint and is projected through a small nozzle. A gas jet of air, oxygen or nitrogen is also passed through the nozzle. The material being cut is vaporised by the intense energy of the beam and ejected by the gas jet. The cutting head travels over the material by computer control, and a very thin, neat cut is produced.

Capacities

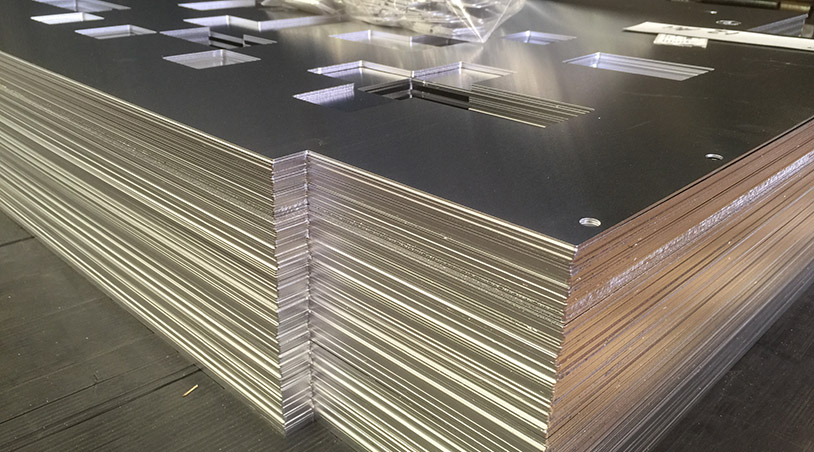

- Maximum sheet size: 3000mm x 1500mm

- Maximum sheet weight: 890kg

- Typical machining tolerance: +/- 0.1mm

- Repetition precision: +/- 0.05mm

- See our Materials page for maximum thicknesses

Pricing is dependent on quantity, material type and thickness, part size and geometry. Send us your requirements and we’ll get back to you with an official quote within 24 hours.

We have several material suppliers who all deliver quality product at competitive rates. We continuously shop around to obtain the best prices, ensuring of course, the material is of prime quality. Alternatively, you can supply your own material.

How long will the job take? Depending on current workload and material availability, our typical turn-around time is usually within one week from receipt of order.