PRESS BRAKE FOLDING

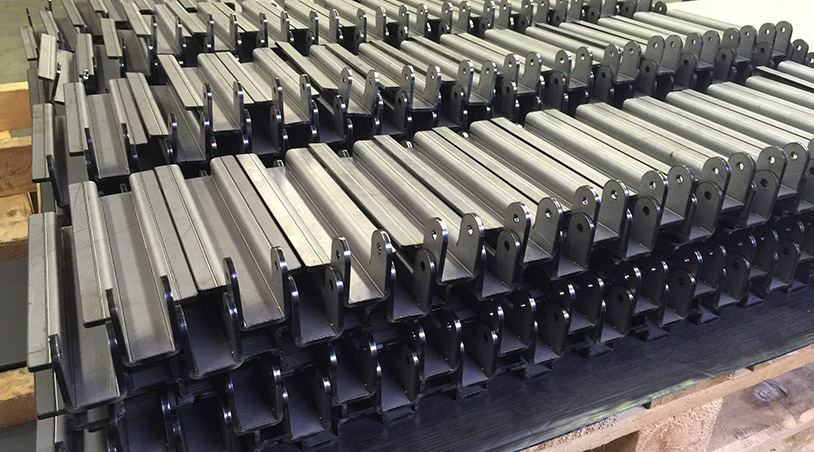

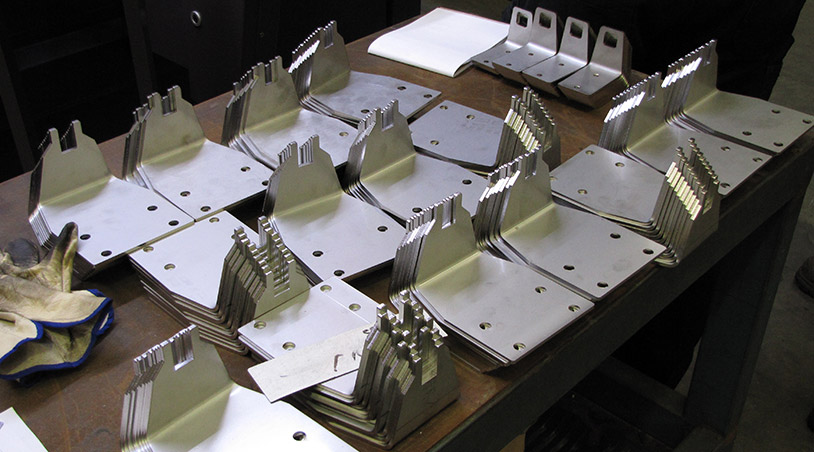

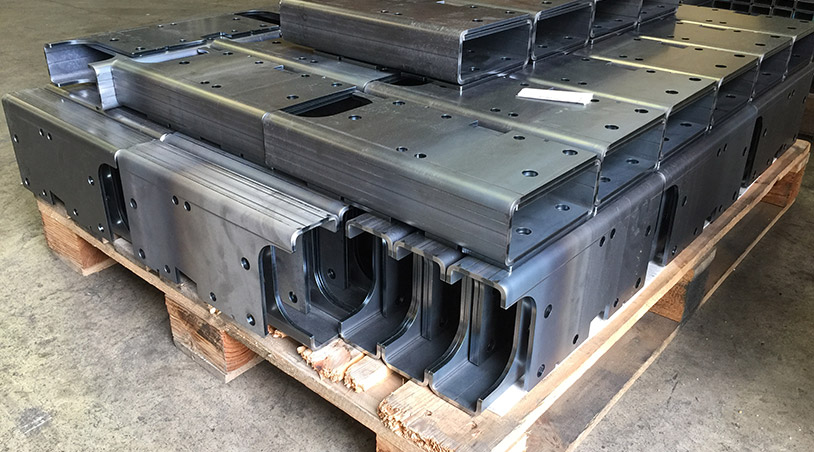

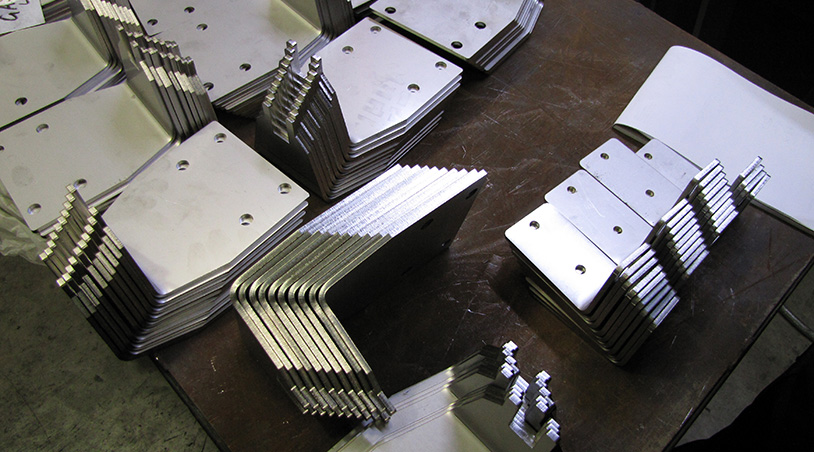

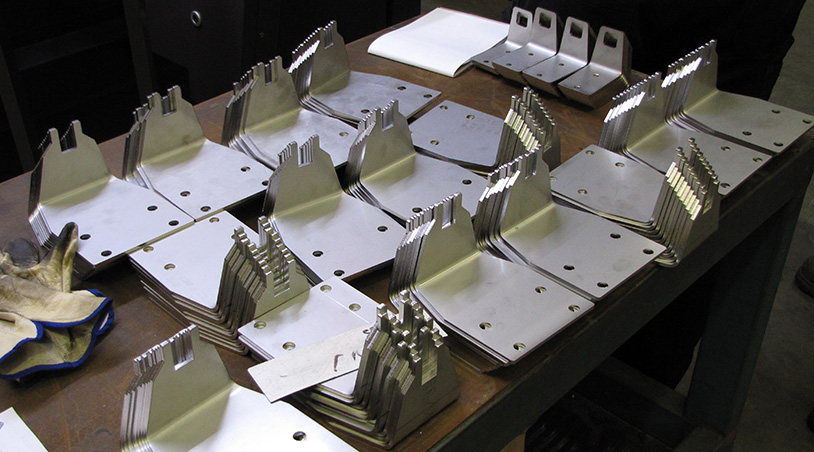

Precision folding of laser cut metal components

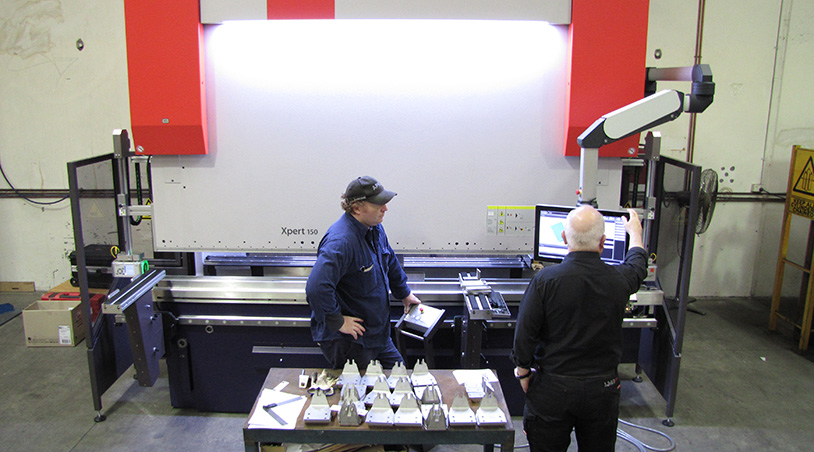

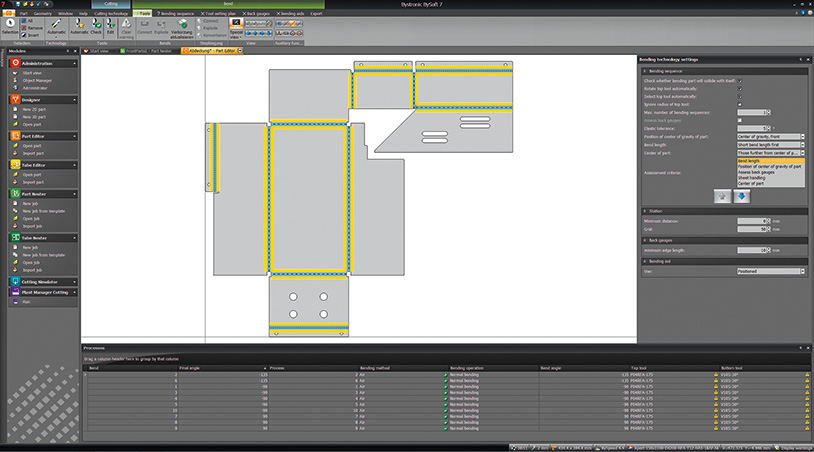

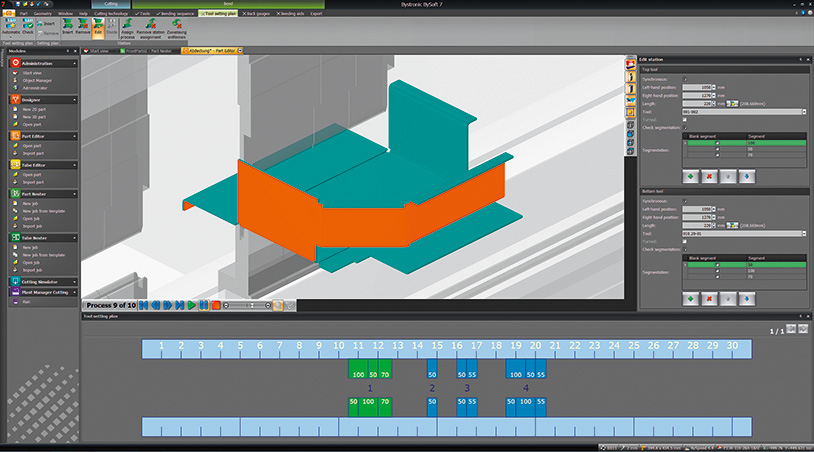

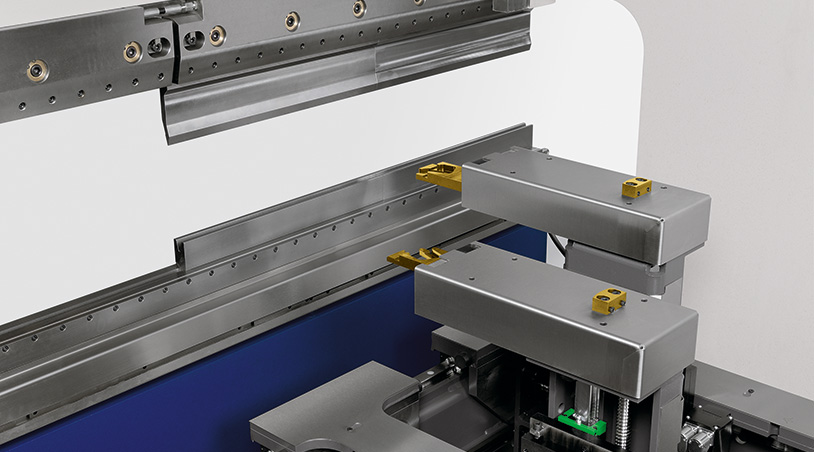

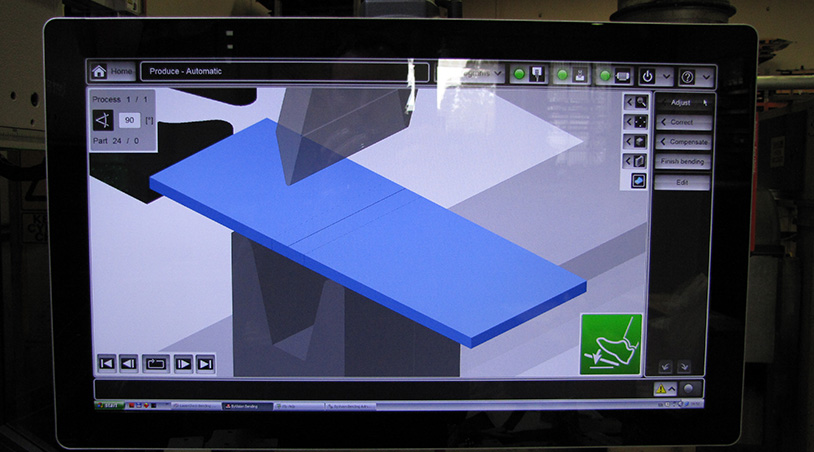

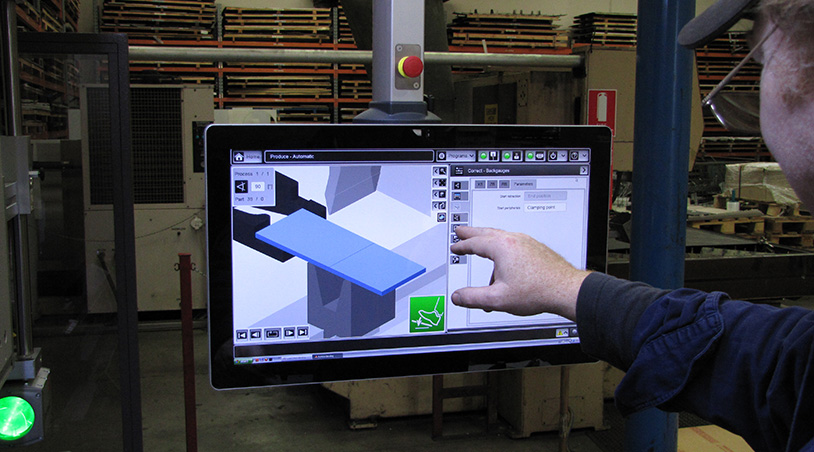

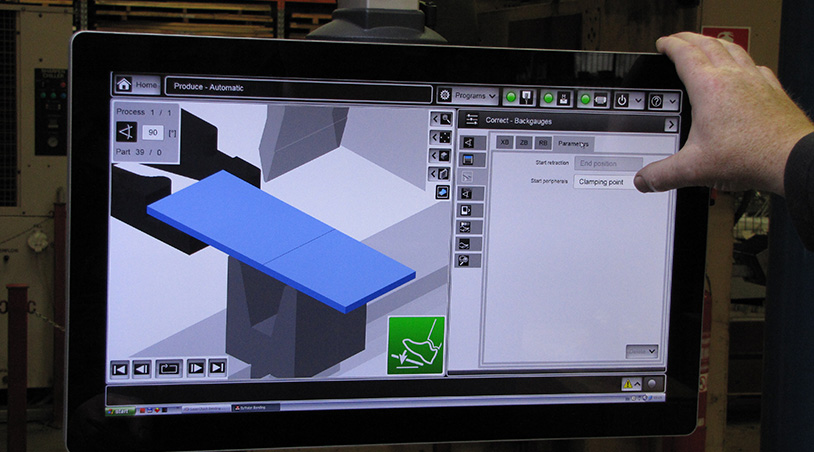

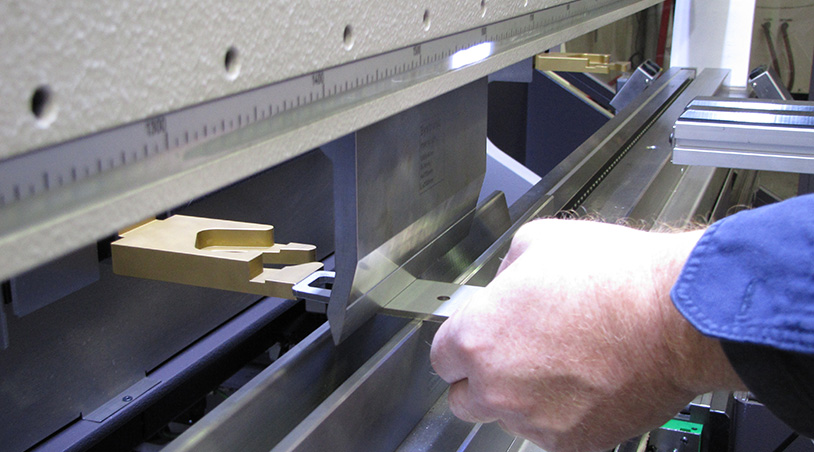

If you need your laser cut parts folded, we have the solutions for you. Our German made press brakes are the most technologically advanced of their type in the world. Our 150 tonne 3.1 metre can handle the heavy work while our new 40 tonne 1 metre can manage the more intricate jobs. Both were the first of their kind installed in the Southern Hemisphere and combined with our Solidworks based 3D software, they cover all bases in folding possibilities.

More information

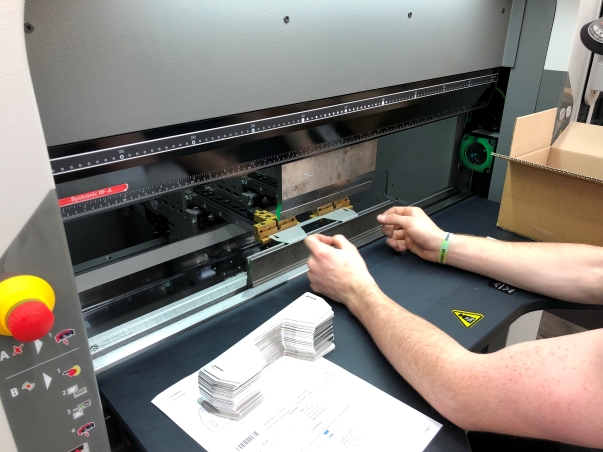

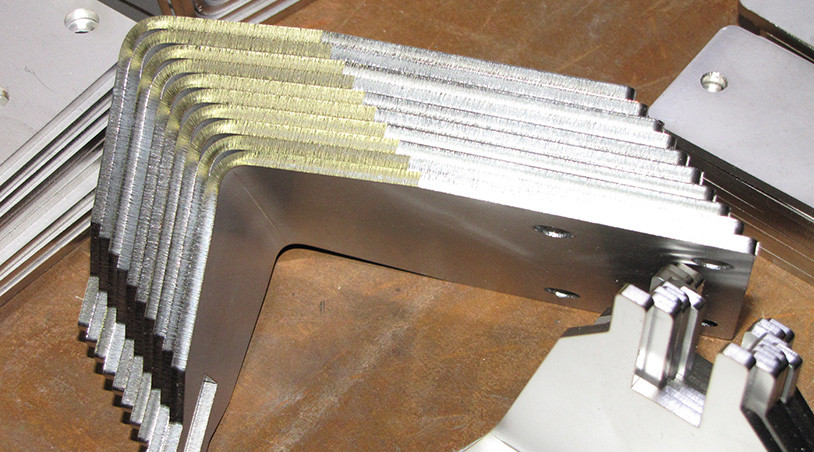

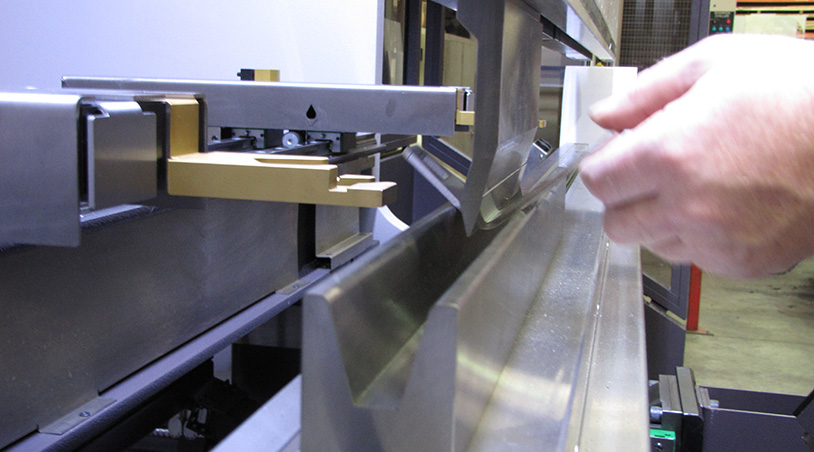

The advanced control systems monitor side frame deflections and system temperatures every eight milliseconds and automatically compensates during each bend. The comprehensive database of bend allowances, tooling shapes and material types, allows for quick and precise bends with extremely high repetition accuracy.

Features:

- Independent 5 axis back gauge

- Intelligent safety system with tool detection

- Dynamic bending pressure regulation

- Quick change hydraulic tool clamping

- Energy saver system

- Optical bend guiding system

- Laser angle measuring system with automatic correction

It depends on the fold length and material type, however a one-metre-long, 90-degree fold, in 10mm mild steel is close to the upper limit.

We have a huge range of tooling so most folds are possible. However, an offline 3D simulation can guarantee success if there is any doubt.

Some plastics can be folded by press brake but metals are ideal.